Why Documentation Matters in Manufacturing

Back in 1937, the Elixir Sulfanilamide tragedy killed 107 people due to unsafe drug ingredients. This disaster forced the U.S. government to create strict documentation rules. Today, GMP documentation requirements are the backbone of quality control in manufacturing. Without proper records, companies risk recalls, fines, and even shutdowns. The FDA reports that documentation failures cause an average $10 million loss per incident.

Core Documentation Requirements

Manufacturing documentation falls into two main categories: procedural records and compliance records. Procedural documents include Standard Operating Procedures (SOPs), testing methods, and emergency protocols. These must be written in active voice with clear steps. For example, an SOP for cleaning equipment should specify exact steps, chemicals used, and safety precautions.

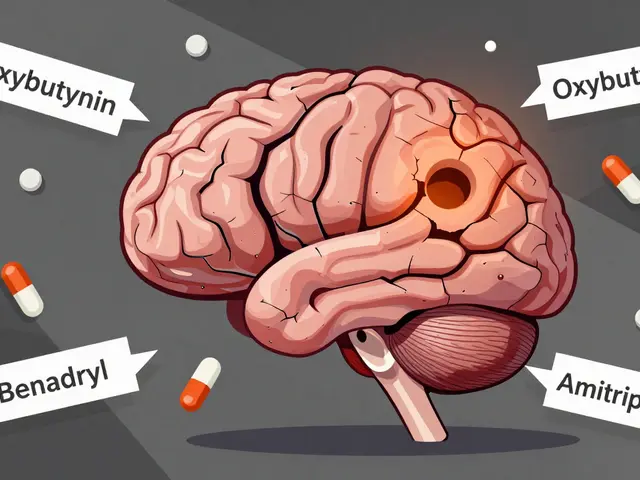

Compliance records must follow ALCOA+ principles. This means each entry must be:

- Attributable: Clearly identify who made the record

- Legible: Handwritten entries must be readable

- Contemporaneous: Created at the time of the activity

- Original: First recording of data, not a copy

- Accurate: Free from errors or alterations

- Complete: All required fields filled in

- Consistent: No contradictions in data

- Enduring: Stored securely for retention periods

- Available: Accessible during audits

Batch records are critical compliance documents. In pharmaceutical manufacturing, each batch must include 28 specific data points like start/end times, equipment IDs, environmental readings, and test results. Missing even one detail can trigger a regulatory warning.

Regional Differences in Documentation Rules

Global regulations vary significantly despite efforts to harmonize standards. The U.S. FDA requires double verification for calculations: one person does the math, another checks it. The EU allows electronic systems to handle this without manual review. Japan mandates all documentation be in Japanese for domestic submissions, creating translation challenges for global companies.

Medical devices face different rules too. The EU's Medical Device Regulation (MDR) requires detailed clinical evaluation reports with specific literature search methods. The FDA's quality system regulations focus more on device master records without the same level of traceability requirements. A 2022 study found manufacturers targeting both U.S. and EU markets spend $2.1 million yearly just to reconcile documentation differences.

Common Challenges in Record-Keeping

Quality teams often struggle with documentation tasks. PharmaTrain's 2023 survey of 452 professionals found QA staff spend 68% of their time on documentation. Common issues include:

- Untimely record creation (42% of FDA observations)

- Inadequate investigation documentation (29%)

- Missing original data (18%)

- Improper record amendments (11%)

Electronic systems introduce new hurdles. Companies must validate these systems per GAMP 5 guidelines, which involves 150+ test cases. A 2022 PDA survey reported 68% of firms experienced data loss during system migrations. One Reddit user shared a $15 million recall caused by undocumented temperature excursions during warehouse transfer.

Best Practices for Effective Documentation

Successful companies follow the "5C" principle: Clear, Concise, Complete, Correct, and Compliant. Writing SOPs at an 8th-grade reading level prevents misinterpretation. The "four-eyes principle" ensures critical records are reviewed by two qualified people.

Electronic Quality Management Systems (eQMS) like MasterControl reduce errors by 55%. Merck implemented this system and cut CAPA closure time from 45 to 22 days. Real-time electronic checklists integrated with manufacturing systems, like Janssen's 2022 setup, slashed documentation errors by 76%.

Future Trends in Manufacturing Documentation

Regulators are pushing for modernization. The FDA's 2023 draft guidance clarifies expectations for hybrid paper-electronic systems, requiring audit trails with 1,000-character entries. By 2025, EU GMP will require risk-based documentation approaches per ICH Q9(R1).

AI-assisted documentation is emerging. Early adopters report 45% less documentation time by auto-generating batch records from manufacturing data. However, regulators remain cautious until validation frameworks exist. The GMP documentation software market is growing rapidly, projected to reach $5.1 billion by 2027.

What are the ALCOA+ principles?

ALCOA+ stands for Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available. These principles ensure records are trustworthy. For example, "Attributable" means clearly identifying who created the record, while "Contemporaneous" requires entries made at the time of the activity. Non-compliance with ALCOA+ is a top reason for FDA warning letters.

Why do FDA and EU documentation rules differ?

Differences stem from historical regulatory paths. The FDA focuses on strict verification steps like dual checks for calculations, while the EU allows electronic systems to handle verification. Japan requires Japanese-language documentation for domestic submissions, creating challenges for global companies. These variations force manufacturers to tailor documentation for each market, increasing costs and complexity.

What is a common documentation mistake?

The most frequent mistake is untimely record creation. FDA data shows 21% of documentation deficiencies involve entries made after the fact. For example, waiting until the end of a shift to log temperature readings misses real-time data. This creates gaps in traceability and can lead to batch rejections. Always document activities as they happen to maintain data integrity.

How do electronic systems improve documentation?

Electronic systems reduce human errors by automating calculations and checks. They enforce ALCOA+ principles through mandatory fields and time-stamping. MasterControl's implementation at Merck cut CAPA closure time from 45 to 22 days. Audit trails automatically track changes, ensuring compliance with 21 CFR Part 11 requirements for electronic signatures and data integrity.

What's the biggest risk of poor documentation?

The biggest risk is product recalls costing millions. A single undocumented temperature excursion during shipping led to a $15 million recall for one company. FDA warning letters often cite documentation gaps as the root cause. Beyond financial losses, poor documentation damages reputation and trust with regulators, potentially leading to shutdowns or legal action.

US documentation rules are superior. EU and Japan need to catch up. 😡

February 7Georgeana Chantie